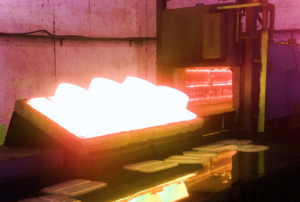

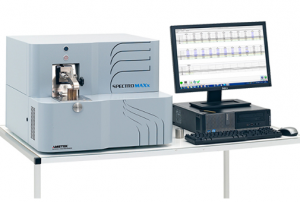

The company specializes in providing impeller products for famous European and American air compressor brand manufacturers and domestic wind turbine manufacturers. Committed to the production of stainless steel and aluminum-titanium alloy raw materials for high-speed impellers, as well as impeller blanks and finished products. The company has a history of nearly 30 years. It is located in the Wusong Economic Development Zone of Yangxing, Baoshan District. It covers an area of 15,000 square meters and has professional production equipment and technical production team. The company focuses on high-end advanced manufacturing and continuous innovation and development. The company relies on vacuum refining, electroslag, heat treatment, multi-axis CNC machining and various aspects of inspection and other excellent manufacturing processes and technologies to ensure product quality in all production links from raw materials to finished products, and is in a leading position in the same industry.

Top 10 manufacturers of centrifugal impellers for air compressors in China

Shanghai Cidong Alloy Materials Co., Ltd. is one of the top ten manufacturers of centrifugal impellers for air compressors in China. Shanghai Cidong Alloy Materials Co., Ltd. is indeed widely recognized as one of the top manufacturers in this specific niche in China. Here are a few key points about their position in the market: Specialization: They are known for specializing in aluminum die-casting and the production of high-precision alloy parts. Their core competency lies in manufacturing components that require high strength and durability. Product Focus: While they make various alloy parts, they are particularly famous for centrifugal impellers (aluminum wheels) used in air compressors, turbochargers, and superchargers. Market Position: Being ranked among the "top ten" manufacturers in China typically implies they have significant production capacity, advanced technology (likely using high-quality die-casting machines and CNC machining), and a strong reputation in the domestic supply chain for air compressor components. Based on their position as a top-tier manufacturer and

How to improve the working efficiency of centrifugal impellers in air compressors?

Improving the working efficiency of centrifugal impellers in air compressors is a multi-faceted challenge that involves aerodynamics, manufacturing precision, and operational strategies. The impeller is the heart of the compressor; any loss here directly translates to higher energy consumption. Here is a comprehensive guide on how to enhance the efficiency of centrifugal impellers, categorized by design, manufacturing, and operation. 1. Advanced Aerodynamic Design The shape of the impeller dictates how smoothly air flows through it. The goal is to maximize energy transfer to the air while minimizing friction and separation losses. 3D Aerodynamic (Twisted) Blading: The Problem: Traditional 2D blades have a constant angle from hub to shroud. This doesn't account for the fact that the air velocity changes significantly from the hub (base) to the tip. The Solution: Use 3D blading (often called "bow" or "tilt" and "lean"). By twisting the blade to match the local inflow angle at every point along its span, you reduce

How to repair a damaged centrifugal impeller in a centrifugal air compressor?

Repairing a damaged centrifugal impeller is a highly delicate and precision-driven task. Because the impeller is the heart of the compressor, operating at extremely high speeds (tens of thousands of RPM), any repair must be flawless to avoid catastrophic failure, imbalance, and damage to the entire compressor. Critical Safety and Performance Warning: Before attempting any repair, you must consult the Original Equipment Manufacturer (OEM) . Many manufacturers have strict policies forbidding repairs on certain types of damage (e.g., base metal cracks, severe blade deformation) due to safety risks. Repairing a non-repairable impeller voids warranties and creates a severe safety hazard. Here is a step-by-step guide to the repair process, typically performed by specialized repair shops. Phase 1: Assessment and Inspection Before any work begins, you must determine if the impeller is repairable. Visual Inspection (Borescope): Identify the type and extent of damage. Repairable: Minor erosion, light pitting, small nicks on blade leading edges, FOD (Foreign

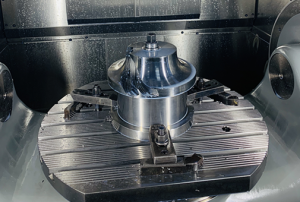

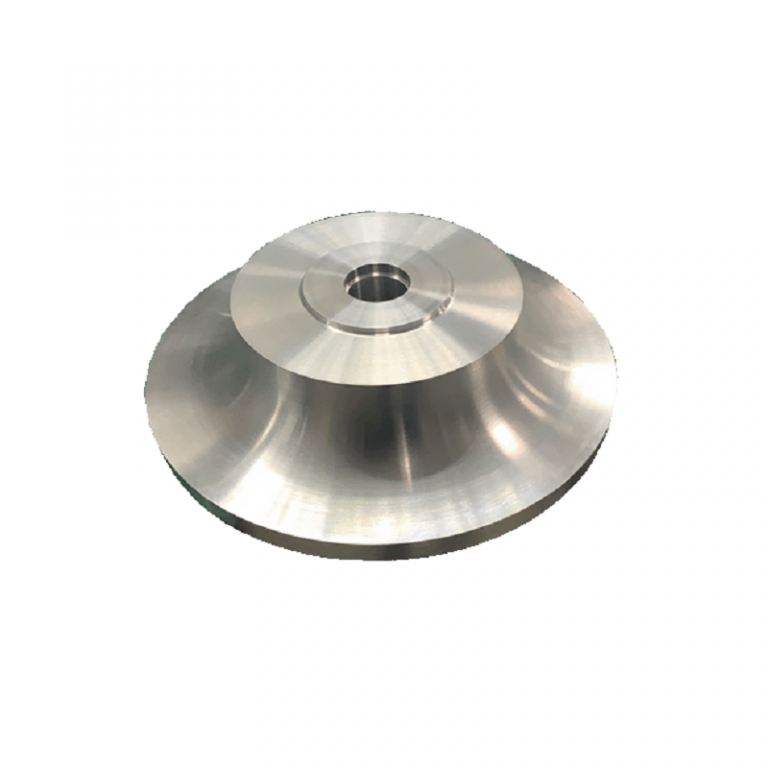

Centrifugal Compressor Impeller Machining

The machining of centrifugal compressor impellers has evolved significantly, with modern techniques focusing on achieving high precision and complex geometries. The dominant method is 5-axis CNC machining from a solid block, but several other processes are also used depending on the impeller's design, material, and application requirements. Here is an overview of the key manufacturing methods. 5-Axis CNC Machining: The Modern Standard For high-performance impellers, particularly those with complex, twisted blades, 5-axis CNC machining from a solid forging (a process often called "machining from solid") is the preferred method. This approach offers superior geometric accuracy, material integrity, and design flexibility. Core Technology: The process relies on sophisticated 5-axis machine tools and CAM software to position the cutting tool optimally relative to the workpiece. Two primary cutting strategies are used: Flank Milling: The side of the cutter is used to machine the blade surface in a single pass. This is highly efficient

Enhancing Centrifugal Impeller Lifespan in Air Compressors

Extending the service life of centrifugal impellers is crucial for compressor reliability, efficiency, and total cost of ownership. It requires a holistic approach spanning design, operation, maintenance, and monitoring. Here is a comprehensive breakdown of key strategies: 1. Design and Material Selection (The Foundation) This is the most critical factor, often determined during procurement. Material Upgrade: Standard materials are often aluminum or 400-series stainless steel. Titanium Alloys: For high-strength, exceptional corrosion resistance, and fatigue resistance in demanding applications. Precipitation-Hardening Stainless Steels (e.g., 17-4 PH): Offer a great balance of strength and corrosion resistance. Duplex Stainless Steels: Excellent for chloride-induced stress corrosion cracking. Nickel-Based Alloys (e.g., Inconel): For very high temperatures and corrosive environments. Advanced Manufacturing: Precision Investment Casting: Provides excellent surface finish and dimensional accuracy, reducing stress concentrations. 5-Axis CNC Milling: Allows for complex, optimized aerodynamic profiles with superb surface integrity. Forging: Creates a superior grain structure for high-integrity impellers. Surface Treatments & Coatings: Anti-Corrosion Coatings: E-coatings, epoxy, or specialized

Analysis of technical pain points of air compressor centrifugal impeller

The centrifugal impeller is the very heart of an air or gas compressor, where mechanical energy is transformed into aerodynamic energy (pressure and velocity). Its performance and reliability are paramount. The technical pain points are complex and interrelated, spanning aerodynamics, structural mechanics, material science, and manufacturing. Here is a detailed analysis of the key technical pain points of an air compressor centrifugal impeller: 1. Aerodynamic & Performance Pain Points Stall and Surge: This is the most critical operational hazard. Impeller Stall: At off-design conditions (especially low flow), airflow separation occurs on the blade surfaces. This creates unsteady, recirculating vortices, leading to vibration, loss of efficiency, and increased blade loading. System Surge: If stall propagates throughout the entire compressor, it can lead to surge—a violent reversal of flow through the machine. This subjects the impeller to extreme cyclic axial and bending loads, often causing catastrophic failure. Choking: At very high flow rates, the flow reaches

Causes of Impeller Damage in Centrifugal Compressors

Damage to the impeller, the heart of a centrifugal compressor, can lead to catastrophic failure, unplanned downtime, and costly repairs. The causes can be broadly categorized into operational, material/environmental, and maintenance-related issues. Here is a detailed breakdown of the primary causes: 1. Operational Causes These are often the most common and preventable causes of damage. Surge: This is the most destructive phenomenon. It occurs when system pressure exceeds the compressor's discharge pressure, causing a violent reversal of flow through the impeller. This results in severe axial vibration, high dynamic stresses, and can bend blades or cause immediate mechanical failure. Liquid Carryover (Slugging): If liquid (water, oil, or process liquid) enters the compressor inlet, it can cause an instantaneous imbalance. Since liquids are incompressible compared to gas, the impeller experiences a massive shock load, potentially breaking blades or the entire wheel. Overspeed: Exceeding the impeller's maximum design rotational speed (due to control system failure or improper operation) creates

What impact will the recent rise in nickel prices have on air compressor centrifugal impeller manufacturers?

The recent rise in nickel prices will have significant and multifaceted impacts on air compressor centrifugal impeller manufacturers, primarily affecting costs, supply chains, and competitive dynamics. Here’s a breakdown: 1. Direct Cost Increase Material Costs: Centrifugal impellers, especially for high-performance or corrosive environments, are often made from nickel-containing alloys (e.g., stainless steel, Inconel, Hastelloy). Nickel is a key alloying element for strength, heat, and corrosion resistance. Higher nickel prices directly raise raw material costs. Procurement Costs: Manufacturers may face price escalation clauses from suppliers or spot-market volatility, squeezing margins if they can’t pass costs to customers immediately. 2. Supply Chain Disruptions Inventory Strain: Manufacturers may struggle to secure nickel/alloy inventories at stable prices, leading to potential shortages or delays. Supplier Negotiations: Long-term contracts might be renegotiated, and suppliers could impose surcharges, adding complexity to supply chain management. 3. Product Pricing & Competitiveness Price Pressures: Manufacturers may need to raise product prices, which could

Turbine Compressor Impeller Factory Overview

Turbine compressor impeller factory points to a highly specialized and technologically advanced sector of manufacturing. Here’s a comprehensive breakdown of what such a factory does, the key processes involved, and how to find or evaluate one. What Does a Turbine Compressor Impeller Factory Do? These factories manufacture the heart of a compressor—the impeller (or rotor). This is the rotating component that imparts kinetic energy to a fluid (air or gas), increasing its pressure and velocity. They are critical in: Aerospace: Turbojet, turboprop, and turboshaft engines (both primary propulsion and auxiliary power units - APUs). Power Generation: Industrial gas turbines for electricity. Oil & Gas: Centrifugal compressors for natural gas processing, pipelines, and refrigeration. Automotive: Turbochargers for internal combustion engines. Marine & Naval Propulsion. Key Manufacturing Processes & Technologies A state-of-the-art factory will have expertise in several of these areas: 1. Design & Engineering: 3D Aerodynamic Design: Using CAD/CAE software (e.g., Siemens NX, CATIA) to design complex

Turbocharger Impeller Function, Design, and Materials

Here is a detailed overview of a turbocharger impeller, covering its function, types, design, materials, and key considerations. Core Function: The Heart of the Turbo The impeller (often called the wheel or inducer) is the rotating component that is fundamental to the turbocharger's operation. There are two key impellers in a turbo: Turbine Impeller/Wheel: Driven by exhaust gases. Compressor Impeller/Wheel: Driven by the turbine via a shaft, it compresses intake air. When people say "turbocharger impeller," they most often refer to the compressor impeller, as it's central to power gains and is highly visible. 1. Turbine Impeller (The Driver) Function: Converts the kinetic energy and heat of exhaust gases into rotational mechanical energy. Location: Housed in the hot side (turbine housing) of the turbo. Design: Typically made of a high-nickel superalloy (like Inconel) to withstand extreme temperatures (often above 950°C / 1750°F) and corrosion. Key Design Variations: Journal Bearing Turbines: Often have a shroud (a surrounding wall) for better efficiency at lower flow rates.