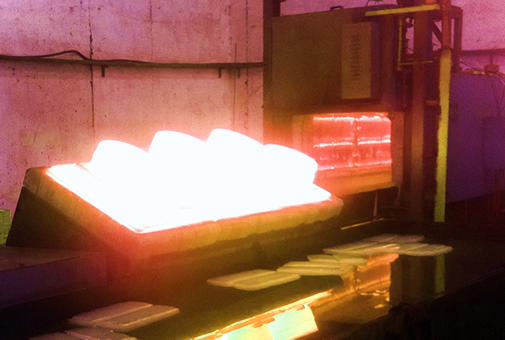

Heat Treatment for the crude steel billet of centrifugal impeller

Heat treating the crude steel billet for a centrifugal impeller is a critical and multi-stage process that transforms a rough, cast or forged piece of steel into a component capable of withstanding high rotational speeds, cyclic stresses, and sometimes corrosive environments.

The goal of heat treatment for centrifugal impeller steel is to achieve a combination of high strength, good toughness, excellent fatigue resistance, and often, specific surface properties.

Here is a detailed breakdown of the typical heat treatment process for a steel billet destined to become a centrifugal impeller:

1. Material Selection (Prerequisite)

The heat treatment path depends entirely on the steel grade. Common choices include:

Low-alloy steels: AISI 4140, 4340, 42CrMo4 (Excellent strength-to-weight, good toughness).

Martensitic stainless steels: AISI 410, 420, 17-4PH (Good corrosion resistance + high strength).

Austenitic stainless steels: AISI 304, 316 (Used more for corrosion resistance; strength comes from cold work or solution strengthening).

Specialty alloys: Inconel 718, Titanium alloys (for high-temperature aerospace applications).

Contact Information

- Tel

+86 17821620679

- Address

No.188 Road Chunhe,

Baoshan District, Shanghai China