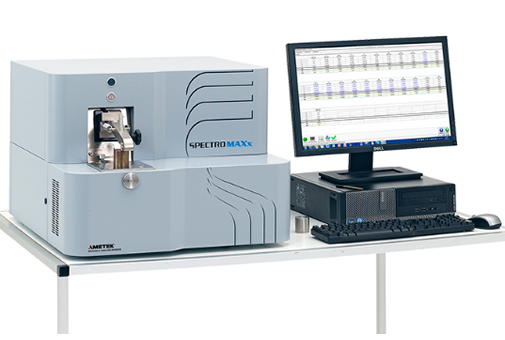

Centrifugal impeller spectrometer testing services

We provide professional centrifugal impeller spectrometer testing services which is a specialized, multi-disciplinary testing need.

"Centrifugal impeller spectrometer testing services" refers to a highly specialized field of engineering testing that combines rotodynamic machinery analysis with spectral diagnostics to evaluate the performance, integrity, and fluid dynamics of centrifugal impellers.

Here’s a detailed breakdown of what these services typically entail, who provides them, and what you should look for.

1. What is Being Tested & The "Spectrometer" Aspect

The term "spectrometer" here is metaphorical. It doesn't usually refer to a chemical mass spectrometer. Instead, it points to the analysis of signals in the frequency domain (spectra) to diagnose impeller behavior. Key signals analyzed include:

Vibration Spectra: From accelerometers on bearing housings. Reveals imbalances, misalignments, blade pass frequencies, resonances, and rubbing.

Dynamic Pressure Spectra: From high-frequency pressure transducers in the volute/diffuser. Crucial for detecting flow instabilities, cavitation, rotating stall, and blade excitation forces.

Noise/Acoustic Spectra: For NVH (Noise, Vibration, Harshness) analysis and detecting aerodynamic phenomena.

Stress/Strain Spectra: From telemetry systems or strain gauges on rotating blades to measure dynamic stresses.

2. Core Testing Services Offered

Specialized labs offer a suite of tests, often on a dedicated impeller test rig or a full pump/compressor stage. Services include:

A. Performance & Aerodynamic/Hydraulic Testing:

Performance Mapping: Measuring pressure ratio (or head), flow rate, efficiency, and power consumption across the operating range.

Flow Field Surveys: Using Particle Image Velocimetry (PIV) or Laser Doppler Velocimetry (LDV) to map velocities inside/behind the impeller. This is a key "spectral" service for fluid dynamics.

Cavitation Testing (NPSH Required): Determining the onset and extent of cavitation using high-speed video and acoustic emission spectra.

B. Structural & Mechanical Integrity Testing:

Modal Analysis (Impact Testing): Identifying the natural frequencies, mode shapes, and damping of the impeller. Critical for avoiding resonance.

Dynamic Strain Measurement: Using rotating telemetry systems or slip rings to measure real strain on rotating blades under operating conditions. The spectral analysis of this strain data is vital for fatigue life prediction.

High-Speed Overspeed Test: Spinning the impeller to a percentage above its maximum rated speed (e.g., 125%) to validate containment and material integrity.

C. Dynamic Diagnostic & Spectral Analysis:

Operational Deflection Shape (ODS) Analysis: Visualizing how the impeller and structure vibrate under operating conditions.

Order Tracking: Analyzing vibration/pressure data synchronous with rotational speed to distinguish speed-related orders from fixed frequency phenomena.

Aeroacoustic Testing: Mapping sound power levels and spectra to meet noise regulations and identify tonal noise from blade pass interactions.

Contact Information

- Tel

+86 17821620679

- Address

No.188 Road Chunhe,

Baoshan District, Shanghai China