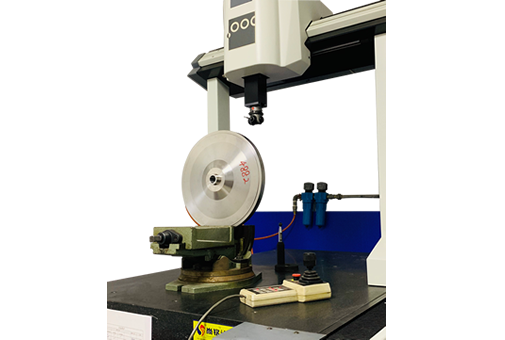

Three coordinates testing for centrifugal compressor impeller

Three coordinates testing essentially means full 3D metrological verification of the impeller’s form, dimensions, and angles to ensure it will perform as designed aerodynamically and mechanically.

Why These "Three Coordinates" (3D) Are Critical:

Centrifugal impellers are complex 3D shapes with compound curves. 2D measurements (like using calipers or micrometers) are insufficient.

Performance depends on precise 3D geometry. Small errors in blade twist or lean can cause imbalance, vibration, or reduced efficiency.

Modern manufacturing (5-axis milling, casting) requires 3D verification to ensure the digital design is accurately realized.

Here’s a breakdown:

1. Geometric Profile Accuracy

Blade Surfaces (Pressure & Suction Sides): The most critical measurement. A CMM probes numerous points along each blade's 3D surface contour to ensure it matches the designed airfoil profile within tight tolerances.

Why it matters: Even minor deviations can drastically affect aerodynamic performance, efficiency, pressure ratio, and surge margins.

2. Dimensional & Positional Accuracy

Key Dimensions:

Hub & Shroud Contours: The meridional flow path geometry.

Leading Edge (Inlet) & Trailing Edge (Outlet) Positions: Axial and radial locations must be precise to ensure proper flow entry/exit and alignment with diffuser.

Throat Area: Critical for determining flow capacity and Mach number.

Blade Heights and Tip Clearances: Affects efficiency and vibration.

Why it matters: Ensures the impeller fits correctly in the assembly and maintains design flow/performance characteristics.

3. Orientation & Angular Relationships

Blade Angles:

Inlet Blade Angle (β1bβ1b): Influences incidence angle and shock losses.

Outlet Blade Angle (β2bβ2b): Directly impacts work input, pressure rise, and slip factor.

Blade Stacking Line: The alignment of blade sections from hub to shroud.

Blade Perpendicularity/Twist: Ensures blades are correctly oriented relative to the axis of rotation.

Why it matters: Correct angles are essential for optimal energy transfer and avoiding flow separation.

Contact Information

- Tel

+86 17821620679

- Address

No.188 Road Chunhe,

Baoshan District, Shanghai China