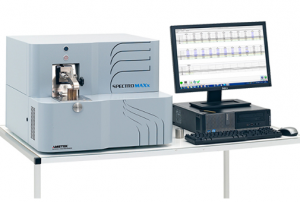

The company specializes in providing impeller products for famous European and American air compressor brand manufacturers and domestic wind turbine manufacturers. Committed to the production of stainless steel and aluminum-titanium alloy raw materials for high-speed impellers, as well as impeller blanks and finished products. The company has a history of nearly 30 years. It is located in the Wusong Economic Development Zone of Yangxing, Baoshan District. It covers an area of 15,000 square meters and has professional production equipment and technical production team. The company focuses on high-end advanced manufacturing and continuous innovation and development. The company relies on vacuum refining, electroslag, heat treatment, multi-axis CNC machining and various aspects of inspection and other excellent manufacturing processes and technologies to ensure product quality in all production links from raw materials to finished products, and is in a leading position in the same industry.

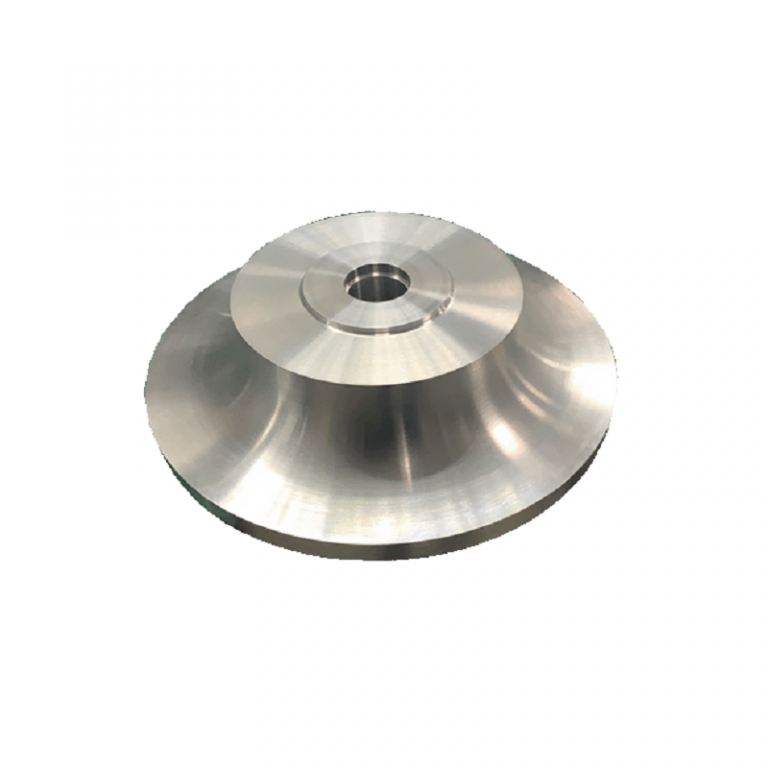

Centrifugal Blower Impeller Design and Applications

The centrifugal blower impeller is the beating heart of any centrifugal blower or fan. It's the rotating component that converts mechanical energy (from a motor) into kinetic energy and pressure in the air or gas. Here’s a comprehensive breakdown of centrifugal blower impellers: Core Function As the impeller rotates, it draws air axially into its eye (center). The air is then captured by the blades, accelerated radially outward due to centrifugal force, and finally expelled at high velocity and increased pressure into the volute (housing casing), which converts the velocity into static pressure. Key Design Characteristics 1. Blade Types & Performance Curves The blade design is the primary factor determining the fan's performance characteristics (pressure vs. flow). Forward-Curved (FC) / Multi-Vane (Squirrel Cage): Blades: Many short blades, curved in the direction of rotation. Performance: Lower speed, generates high volume flow at moderate static pressures. Its performance curve has a "dip," making it unsuitable for systems with varying

Best Materials for Centrifugal Impellers

The "best" material for a centrifugal impeller depends entirely on the specific application, operating conditions, and performance requirements. There is no single "best" material, but there is a best material for a given job. Here’s a breakdown of the most common materials, their advantages, disadvantages, and typical applications. Key Selection Criteria: Corrosion/ Erosion Resistance: Against the pumped fluid (acids, seawater, slurries). Strength & Fatigue Resistance: To withstand centrifugal forces at high RPM. Weight: Affects bearing life and rotor dynamics. Cost: Material and manufacturability (casting, machining). Temperature: For hot or cryogenic services. Common Materials and Their Applications 1. Stainless Steels (The Most Common Category) Types: 304/304L, 316/316L, Duplex (2205), Super Duplex (2507), 17-4 PH (precipitation-hardening). Advantages: Excellent all-around corrosion resistance, good strength, readily available, cost-effective for many services. Disadvantages: Can be heavy; not suitable for very strong acids or chlorides without careful selection. Best For: The vast majority of general industrial applications (water, chemicals, food, pharmaceuticals). 316L is the "workhorse" for chemical

Centrifugal Blower Impeller Design and Function Overview

Here is a comprehensive overview of a centrifugal blower impeller, covering its function, design, types, key considerations, and common applications. Core Function The impeller is the rotating heart of a centrifugal blower (or fan). Its primary function is to transfer energy from the motor to the air/gas by accelerating it radially outward. It converts rotational kinetic energy into static pressure and kinetic energy in the air stream. How It Works (The Principle) Air Intake: Air enters the impeller axially (parallel to the shaft) through the eye (the center inlet). Acceleration: The rotating blades (vanes) capture the air. Centrifugal force flings the air radially outward into the scroll (volute) casing. Pressure Rise: As the air moves from the small-radius eye to the large-radius tip, its velocity increases dramatically. This high-velocity air then enters the expanding volute casing, where velocity is converted into static pressure (Bernoulli's principle). Discharge: The pressurized air is discharged at the blower outlet, ready for its

Types and Functions of Centrifugal Pump Impellers

Impellers are the heart of a centrifugal pump, and their design directly determines the pump's performance, efficiency, and suitability for an application. They are classified in three primary ways: 1. Based on Flow Direction (Path of Fluid Through Impeller) This is the fundamental classification. Radial Flow Impeller: The most common type. Fluid enters axially and is discharged radially (90° to the shaft). Generates high head at low flow. Used in most standard centrifugal pumps for water supply, industrial processes, and high-pressure applications. Mixed Flow Impeller: Fluid enters axially and is discharged at an angle (between 0° and 90°). Provides a balance of moderate flow and moderate head. Often used in irrigation, drainage, and larger water circulation pumps. Axial Flow Impeller (Propeller): Fluid enters and discharges nearly parallel to the shaft (axial direction). Designed for very high flow rates at very low head. Common in stormwater pumping, flood control, and large-scale circulation (e.g., cooling water intakes). 2. Based on Suction Type (Number of Inlets)

What are the functions of a centrifugal impeller in a centrifugal air compressor?

The centrifugal impeller is the heart of a centrifugal air compressor, and its functions are all centered around converting mechanical energy into pneumatic energy. Here are its primary functions, broken down: Core Functions: 1. Energy Transfer & Conversion Primary Role: The impeller takes mechanical energy (rotational motion and torque from the driver, typically an electric motor or turbine) and transfers it to the air. Conversion: It converts this mechanical input energy into kinetic energy (velocity) and pressure energy (pressure). 2. Acceleration of Air / Imparting Velocity As the impeller rotates at high speeds (often 20,000 - 100,000+ RPM), the curved blades (vanes) grab the air that is drawn axially into the eye (center) of the impeller. The air is forced to move radially outward along the blade passages. Due to the impeller's high rotational speed and the centrifugal force, the air is violently accelerated to a very high velocity as it leaves the impeller tip. 3. Pressure Generation (via

CD impeller is the supplier of high quality centrifugal impeller from China

CD Impeller is a leading Chinese manufacturer and supplier specializing in high-quality centrifugal impellers. We combine advanced manufacturing technology with rigorous quality control to produce precision impellers for a wide range of industrial applications, including: HVAC & Ventilation: Fans, air handlers, and exhaust systems. Industrial Processing: Pump impellers for water treatment, chemical processing, and irrigation. Air Moving Equipment: Dust collectors, cooling units, and pneumatic conveyors. Specialized Machinery: Custom impellers for unique OEM applications. Our Strengths: Quality Materials: Use of premium alloys, stainless steels, and composites. Precision Engineering: Advanced CNC machining, casting, and dynamic balancing. Customization: Ability to design and produce impellers to meet specific performance criteria (CFM, pressure, size, material). Competitive Pricing: Leveraging efficient manufacturing to provide excellent cost-effectiveness. Reliable Supply: Consistent output and dependable delivery schedules. Why Source from China with CD Impeller?Sourcing from China offers significant advantages in cost and scale. Partnering with a specialized supplier like CD Impeller ensures you receive components that meet international standards for performance,

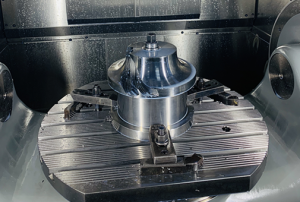

Three coordinates testing for centrifugal impeller

When discussing "three coordinates" for testing a centrifugal impeller, it typically refers to the different frames of reference or measurement systems used to analyze its performance, design geometry, and flow physics. Here are the three primary coordinate systems used: 1. Cartesian Coordinates (X, Y, Z) Purpose: Design, Manufacturing, and Static Measurement. Description: The absolute, stationary reference frame. This is the language of CAD models, CNC machines, and coordinate measuring machines (CMM). Use in Testing: Dimensional Verification: Measuring the exact blade profile, hub and shroud contours, leading and trailing edge positions. Vibration Analysis: Measuring casing vibrations in X, Y, Z directions during testing. Computational Fluid Dynamics (CFD) Setup: The computational domain (inlet, volute, etc.) is defined in Cartesian coordinates. Testing Context: "The CMM probe recorded the blade surface at 500 points defined in (X, Y, Z) to compare against the CAD nominal geometry." 2. Cylindrical Coordinates (R, θ, Z) Purpose: Flow Analysis and Performance Evaluation. Description: A rotating frame aligned with

Centrifugal Compressor Impeller Operation Overview

Here is a comprehensive overview of a centrifugal compressor impeller, the heart of a centrifugal compressor. Core Definition The impeller is the rotating component of a centrifugal compressor. Its primary function is to transfer energy from a driving motor (or turbine) to the fluid (typically air or gas) by accelerating it radially outward. This converts mechanical shaft work into kinetic energy and pressure. Key Design Features & Terminology Hub: The central solid disc that mounts onto the compressor shaft. Blades/vanes: The curved airfoils attached to the hub. They are the critical elements that guide and energize the fluid. Their shape (backswept, radial, or forward-swept) is crucial for performance. Shroud (or Cover): Open Impeller: No shroud; blades are open. Used for dirty gases or suspended solids (e.g., some industrial compressors). Semi-Open Impeller: A shroud on one side (usually front). Common in mid-range applications. Closed Impeller: Blades are fully enclosed by a hub and shroud. Highest efficiency, most common in clean gas

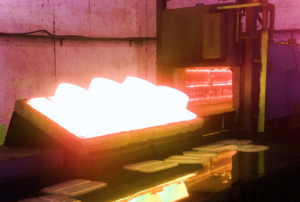

Heat Treatment for Centrifugal Impellers Explained

Heat treatment is a critical, non-negotiable process for most centrifugal impellers, directly determining their performance, lifespan, and safety. Here’s a detailed breakdown of why it's done, common methods, and materials involved. 1. Primary Objectives of Heat Treatment for Impellers The main goals are to: Increase Strength and Hardness: To withstand immense centrifugal forces (can exceed 100,000 times gravity) and prevent deformation. Improve Fatigue Resistance: To endure millions of cyclic stress reversals without cracking. Relieve Internal Stresses: To eliminate residual stresses from casting, forging, welding, or machining, which can cause distortion or premature failure in service. Enhance Toughness (Impact Resistance): Especially for impellers in cryogenic service or those that may face foreign object damage. Optimize for Specific Environments: Such as corrosion or heat resistance. 2. Common Heat Treatment Processes by Material A. For Aluminum Alloy Impellers (Common in HVAC, Aerospace, some automotive) Typical Alloys: 356.0, A356.0, 6061, 2618. Standard Process: Solution Heat Treatment & Aging (Precipitation Hardening) Solution Treatment: Heated to ~990°F

Centrifugal Compressor Impeller Types Overview

The two fundamental types of centrifugal compressor impellers are classified based on the direction in which the blades curve relative to the direction of rotation: 1. Backward-Leaning Impellers (Backward-Curved) Blade Direction: The blades curve against the direction of rotation. Key Characteristics: Higher Efficiency: Provides the best thermodynamic efficiency of the three main types. The blade geometry allows for a more gradual and efficient conversion of kinetic energy into pressure in the diffuser. Non-Overloading Power Characteristic: The required power peaks and then decreases as flow increases, preventing motor overload at high flows. Wide Operating Range: Generally offers a broader stable operating range. Higher Pressure Rise per Stage: Compared to radial blades, but typically lower than forward-leaning for a given tip speed. 2. Forward-Leaning Impellers (Forward-Curved) Blade Direction: The blades curve in the same direction as the rotation. Key Characteristics: Highest Pressure Rise per Stage: For a given impeller diameter and speed, it generates the highest static pressure rise. Compact Size: Can achieve a required pressure