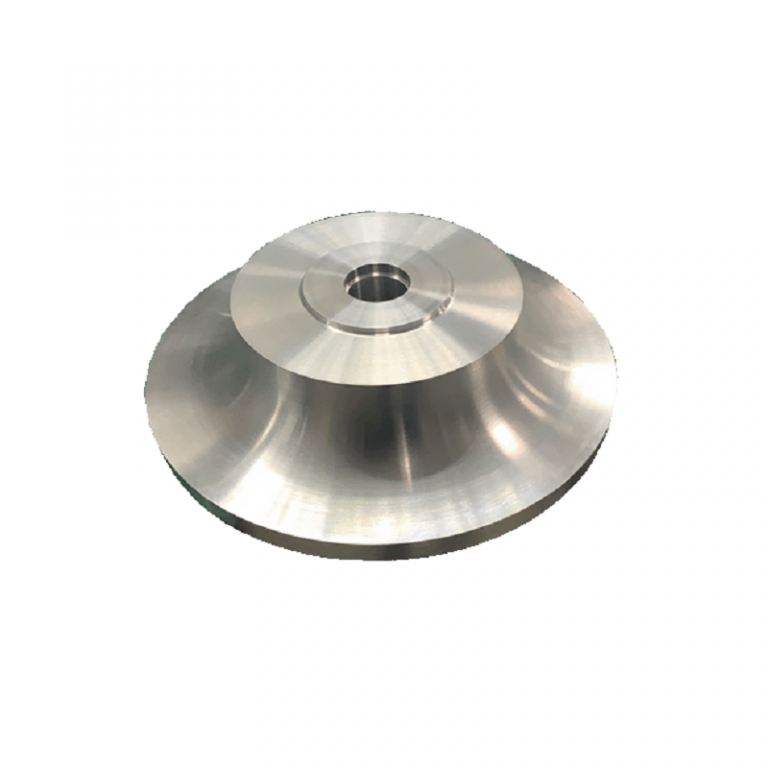

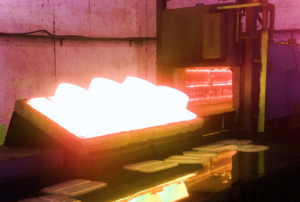

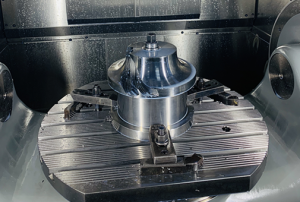

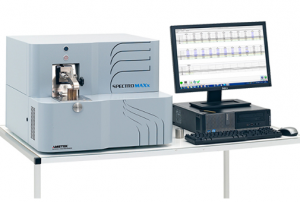

The company specializes in providing impeller products for famous European and American air compressor brand manufacturers and domestic wind turbine manufacturers. Committed to the production of stainless steel and aluminum-titanium alloy raw materials for high-speed impellers, as well as impeller blanks and finished products. The company has a history of nearly 30 years. It is located in the Wusong Economic Development Zone of Yangxing, Baoshan District. It covers an area of 15,000 square meters and has professional production equipment and technical production team. The company focuses on high-end advanced manufacturing and continuous innovation and development. The company relies on vacuum refining, electroslag, heat treatment, multi-axis CNC machining and various aspects of inspection and other excellent manufacturing processes and technologies to ensure product quality in all production links from raw materials to finished products, and is in a leading position in the same industry.

In which industries are centrifugal impellers primarily used?

Centrifugal impellers are critical components in centrifugal pumps, blowers, compressors, and turbines. Their primary function is to transfer energy to a fluid (liquid or gas) by increasing its pressure and kinetic energy through rotational motion. Consequently, they are foundational to a vast array of industries. Here are the primary industries where they are used: 1. Water & Wastewater Treatment Applications: Raw water intake, filtration, chemical dosing, sewage transfer, aeration basins, and final effluent discharge. Purpose: Moving large volumes of water and wastewater through various treatment stages. Aeration impellers are crucial for introducing oxygen into biological treatment processes. 2. HVAC (Heating, Ventilation, and Air Conditioning) Applications: Commercial and residential air handlers, cooling towers, chillers, and furnaces. Purpose: Circulating air, chilled water, and hot water to regulate temperature and air quality in buildings. 3. Oil, Gas, and Petrochemical Applications: Crude oil transfer, pipeline boosting, refinery process pumps, LNG (liquefied natural gas) processing, and chemical feedstock transfer. Purpose: Handling a wide range of

How to make an impeller for centrifugal air compressor?

Making a centrifugal compressor impeller is a serious engineering and manufacturing challenge due to the extreme forces, tolerances, and aerodynamic requirements. It's not a typical DIY project, but understanding the process is fascinating. Here is a comprehensive guide, moving from concept to finished part, with emphasis on the critical considerations at each step. Severe Warning & Disclaimer A centrifugal compressor impeller operates at tens of thousands to over 100,000 RPM. A failure due to poor design, material, or manufacturing is catastrophic—equivalent to a grenade exploding. This guide is for educational understanding only. Professional design, material certification, precision machining (CNC), and dynamic balancing are absolutely mandatory for any functional impeller. Phase 1: Design & Engineering This is the most critical phase. You cannot just "make a shape." Define Requirements: Mass Flow Rate: How much air (kg/s or CFM) do you need? Pressure Ratio (or Boost Pressure): What outlet pressure do you need? Rotational Speed (RPM): Determined by your driver (motor,

What are the types of centrifugal impellers?

Centrifugal impellers are the heart of a centrifugal pump, blower, or compressor, and their design is critical for performance. They are classified based on several key characteristics. Here’s a detailed breakdown of the main types: 1. Based on Mechanical Construction (Shroud Design) This is the most fundamental classification, relating to how the blades are enclosed. Open Impeller: Design: Blades are attached to a central hub without any side walls (shrouds). The blades are open on both sides. Advantages: Less prone to clogging, easy to clean and inspect. Often less expensive to manufacture. Disadvantages: Lower efficiency due to significant fluid recirculation (leakage) between the blades and the pump casing. Requires careful clearance adjustment. Lower structural strength. Applications: Slurry pumps, wastewater pumps, and pumps handling fluids with suspended solids or stringy materials. Semi-Open (or Partially Open) Impeller: Design: Blades are attached to a hub with a single shroud (wall) on one side, usually the back side. The front side

What is the function of an impeller in a centrifugal air compressor?

In a centrifugal air compressor, the impeller is the heart of the machine and its primary rotating component. Its core function is to transfer kinetic energy from the motor/driver to the air, accelerating it and converting that energy into pressure. Here’s a detailed breakdown of its functions: 1. Primary Function: Energy Transfer & Acceleration The impeller is a high-speed rotor with curved blades (vanes). As it spins (typically at 10,000 - 100,000 RPM), the air between its blades is forced outward radially from the center (eye) to the periphery. This centrifugal action massively increases the air's velocity (kinetic energy). 2. Key Sub-Functions and Roles: Air Intake & Direction: Air enters axially through the "eye" of the impeller. The impeller's geometry immediately captures and directs the flow radially outward. Creating Centrifugal Force: The spinning motion imparts a powerful centrifugal force on the air molecules, flinging them toward the outer diameter. This is the namesake "centrifugal" effect. Velocity Increase: The curved